Academics . Curriculum . Fabrication Studios . Fabrication Studios and Equipment

Fabrication Studios and Equipment

The fabrication studios include the wood shop; plastics shop; machining shop; metal shop; plaster/stone room; oil clay room; the spray paint booth; and the spray mount room. Each includes a wide variety of sophisticated equipment for students to use.

Wood Shop

The wood shop is available to help students develop projects relating to woodworking and building objects with wood. The shop features ample workspace, equipment and tools to help research and conduct processes that include surfacing, cutting, shaping, sanding, turning, drilling and fastening.

Equipment includes:

1 panel saw

3 jointers (surfacing)

3 planers (thickness)

5 band saws (cutting/ resawing)

2 saw stop table saws

2 miter saws

2 router tables

3 drill presses

1 combination sander

1 large edge sander

1 double disc sander

2 spindle sanders

1 wide belt sander (37”)

2 wood lathes

1 scroll saw

1 Tormek hollow grinder/sharpener

worktables

hand tools

hand-held power tools (including a nice selection of the Festool lineup)

Plastics Shop

The plastics shop is dedicated to work involving plastic and foam for making objects and sculpture. Processes conducted in the plastic shop are surfacing, cutting, shaping, sanding, drilling and gluing.

Equipment includes:

2 band saws (cutting/ resawing)

1 SawStop table saw

1 miter saw

1 router table

1 drill press

1 combination sander

2 spindle sanders

1 bench lathe

1 scroll saw

1 vacuum former

Machining Shop

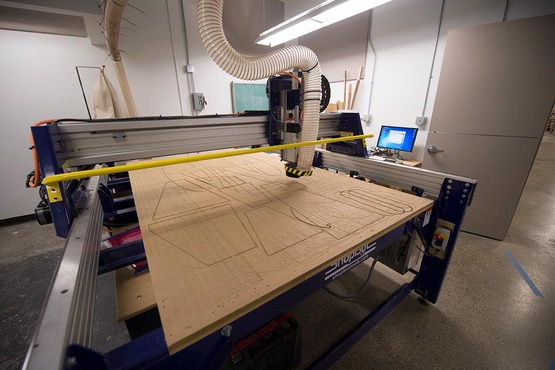

The machining shop is where you’ll work on milling/drilling, tapping, turning, grinding, and the CNC milling machine. Access to the equipment in this space requires additional training.

The machine shop contains:

1 vertical mill

1 metal lathe

1 bench grinder (with vacuum assist)

1 shopbot CNC milling machine (60” x 96” bed with a 6-inch vertical clearance)

Plaster/Stone Room

The plaster/stone room is dedicated to the use of plaster, concrete and stone carving. Plaster can be used for mold making, such as ceramic slip-cast molds. Concrete is being used as a cast-able material for sculptural forms or tabletops. The worktables in this space are capable of handling mold making and stone carving. The brick saw is able to cut ceramic, stone and concrete which can be used in a three dimensional application.

The plaster/stone room contains:

1 brick saw

1 large-capacity pound scales

1 double-station sinks

coddle boards for plaster molds

work tables

air filtration safety system

Metal Shop

Our well-equipped metal shop provides students with the equipment to carry out the processes involved in metal fabrication.

These processes include:

sheet metal forming, breaking, rolling

hot and cold bending

sand blasting

welding (TIG, MIG, spot)

tube Bending

surface Finishing

cutting (cold saw, band saw, shear, plasma cutter, oxy/acetylene)

forging

drilling

Metal shop equipment:

1 vertical band saw

2 drill presses

1 combination sander

1 belt sander

1 horizontal band saw

1 foot shear

1 bending break

1 finger break

1 slip roller

1 bender

1 plasma cutter

cutting torches

1 TIG welder

3 MIG welders

1 large capacity gas forge and anvil

1 shop crane

1 sheet metal tack welder

2 bench grinders

1 sand blaster cabinet

Spray Paint Booth

The spray paint booth is a dedicated space for applying solvent-based finishes and solvent- or water-based painting via a spraying application.

Equipment includes:

2 storage cabinets for flammables

2 large mobile worktables

3 small mobile worktables

ceiling-mounted hanging drying rack

Spray Mount Room

The spray mount room is dedicated to cutting and mounting or laminating material using spray adhesive.

Equipment includes:

2 down draft tables

1 large cutting table

2 heavy straight edges

1 flammables storage cabinet